How to Choose the Right Fully Automatic Circular Saw Machine:

In an industry where every millimeter matters and every second counts, choosing the right Fully Automatic Circular Saw Machine is not just a purchase—it’s a long-term investment in your productivity, precision, and profitability.

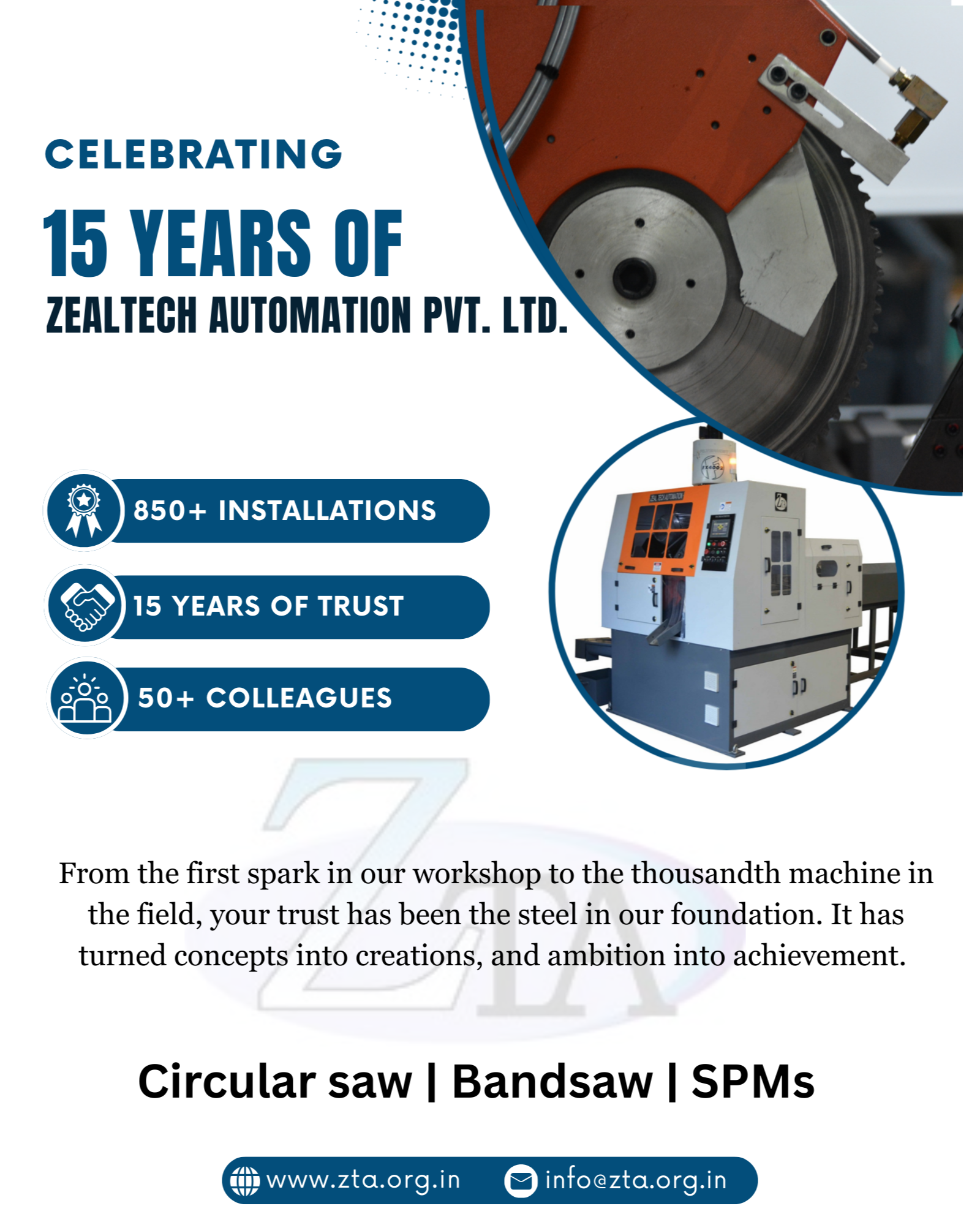

At Zeal Tech Automation Pvt. Ltd., with over 850+ machines installed across India, we’ve helped countless manufacturers make the right choice. Backed by our engineering expertise and India’s largest indigenous circular saw machine (cutting up to 275 mm diameter), here’s everything you need to know to select the perfect model for your shop floor.

🎯 1. Understand Your Cutting Requirements

Start by identifying the type of material, bar diameter, and cut length you need to process:

For solid bars of 40 mm diameter, you’ll need a machine that delivers 3.5–4.5 seconds per cut, resulting in 720–925 cuts per hour.

For 80 mm diameter, ideal performance is 8.5–9.5 seconds per cut, or 340–380 cuts per hour.

For 100 mm diameter, cutting speed should range from 13.5–14.5 seconds, equating to 220–240 cuts per hour.

These performance metrics (subjected to optimum conditions) will help narrow down machines based on daily output targets.

📏 2. Demand Precision—Backed by Numbers

Always verify the machine’s accuracy metrics. ZealTech’s ZTA SONIC FANC machines are engineered for:

Length accuracy: ±0.05 mm (On bright Bars)

Taper accuracy: ±0.05 mm

Face parallelism: 0.050 microns

Surface finish: R A value 0.6–0.8

These tolerances are critical in reducing post-processing operations and ensuring part consistency—especially in automotive, aerospace, and forging applications.

💰 3. Look at Long-Term Cost Savings

A circular saw machine should not just cut metal—it should cut costs:

Save 1.5 mm of material per cut compared to bandsaws

Replace up to four traditional bandsaw machines with one high-speed circular saw

Lower labor and energy costs through automation

Extend tool life with precision clamping and controlled RPM

All these factors contribute to lower cost-per-cut and faster ROI.

⚙️ 4. Evaluate Automation & Usability

A truly Fully Automatic Circular Saw Machine must offer:

Auto loading and feeding systems

Servo-controlled length settings

Smart HMI interfaces for real-time control

Safety interlocks and diagnostics

ZealTech’s machines are built to operate with minimal human intervention, 24x7 reliability, and easy maintenance for shop-floor operability.

🏭 5. Match the Machine to Your Industry

Different industries demand different strengths. For example:

Forging plants require fast solid-bar cutting with tight taper tolerance.

Bright bar producers need ±0.05 mm (On bright Bars) consistency and surface perfection.

Automotive manufacturers depend on cutting cycles of under 5 seconds with repeatable precision.

Make sure the machine you choose aligns with your sector’s standards and tolerances.

🔚 Conclusion: Invest in Precision, Partner with ZealTech

Choosing the right Fully Automatic Circular Saw Machine isn’t about buying the most powerful system—it’s about investing in the right combination of speed, accuracy, and efficiency for your exact application.

With ZTA SONIC FANC machines from Zeal Tech Automation Pvt. Ltd., you’re not just buying a machine—you’re gaining a performance advantage backed by years of experience, field-proven engineering, and unmatched customer satisfaction.

Contact Information

Team ZEALTECH AUTOMATION PVT. LTD.

📧 Email: info@zta.org.in | zealtech.india@gmail.com

📞 Call: +91 93731 63900 | +91 93707 91841.