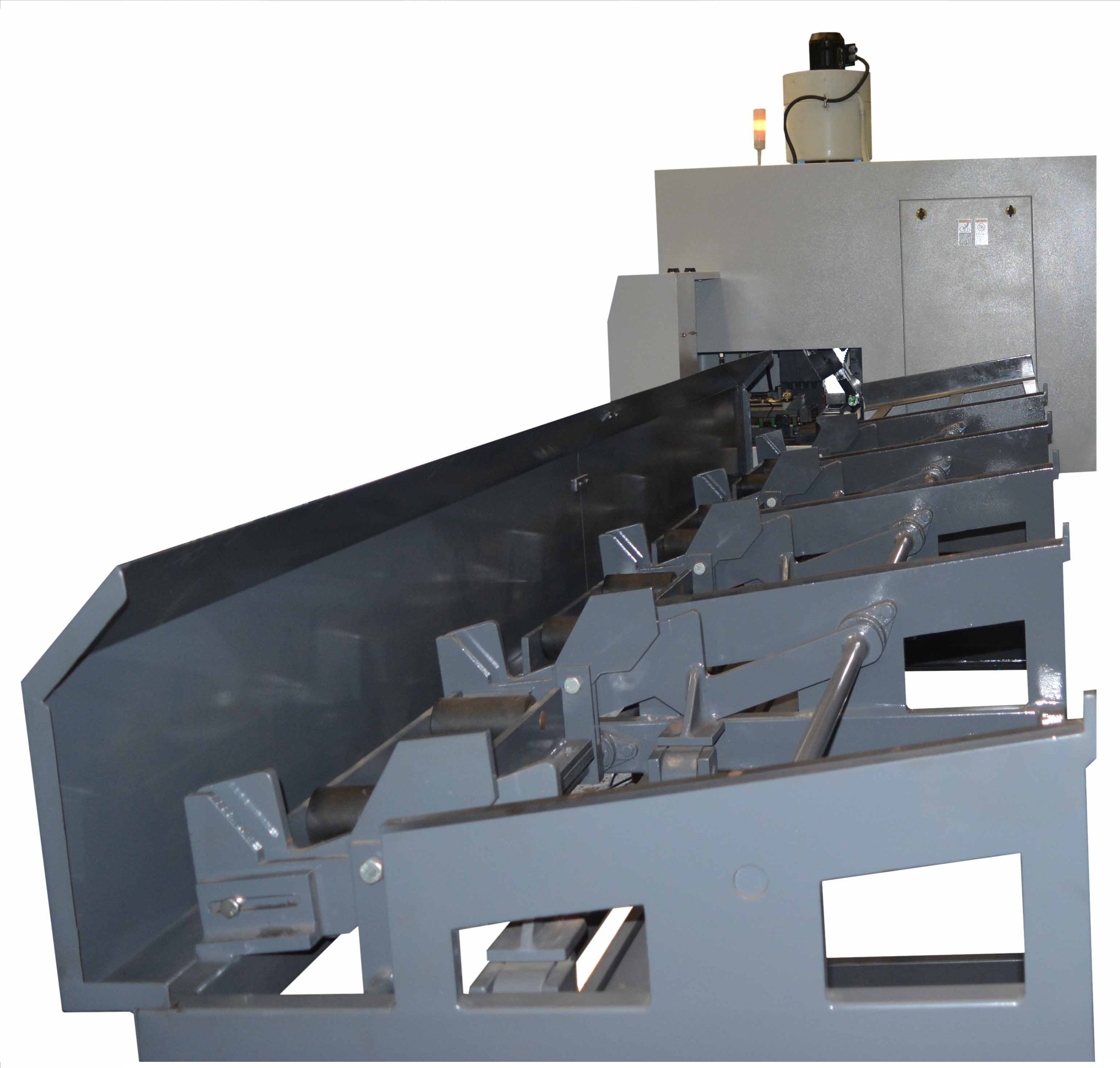

Zealtech offers a comprehensive range of automatic material handling solutions designed to seamlessly integrate with our high-performance circular saw machines. These systems are engineered to optimize productivity, enable unmanned operations, and ensure high precision and reliability in demanding cutting environments. 1) AUTO-LOADER Automatic Material Feeding System Zealtech’s Autoloader is built to automate the feeding of raw material into the machine, enabling uninterrupted operations even for material lengths exceeding 6 meters. It ensures a stable, precise, and impact-free feeding process for a wide range of material types and profiles. Configurations: Standard Autoloader: Equipped with an inclined loading magazine, this design enables smooth, impact-free loading, reducing material damage and ensuring consistent feed rates. Also includes workpiece start-point detection, allowing precise identification of the cut start point, ensuring accurate and stable cutting throughout the operation. Flapper Loader (Optional): Designed for automatic handling of various cross-sectional profiles, including: Round, Hexagonal, Rectangular, Square and other complex shapes. Bucket Loader (Optional): Enables bundle loading of raw materials, significantly reducing manual effort and increasing overall material throughput. 2) AUTO-UNLOADER Automatic Workpiece Discharge System The Autounloader is engineered to efficiently handle the removal of finished workpieces, with multiple configurations available based on the length and size of the cut materials. Configurations: Mini Unloader: Ideal for short-length workpieces, offering a compact solution with quick, efficient unloading for high-speed cutting cycles. Motorized Unloader: Designed to accommodate longer cut lengths, this configuration ensures smooth and controlled discharge of workpieces, maintaining surface quality throughout the unloading process. We invite your esteemed inquiry for our products to provide you a tailored offer. We look forward to your order and a long-term, mutually beneficial business relationship. Please find the attached catalogue at our website: www.zta.org.in Assuring you of our best services at all times. Best regards, Team ZEALTECH AUTOMATION PVT. LTD. Email: info@zta.org.in / zealtech.india@gmail.com Call: 9373163900 / 9370791841

Send Message