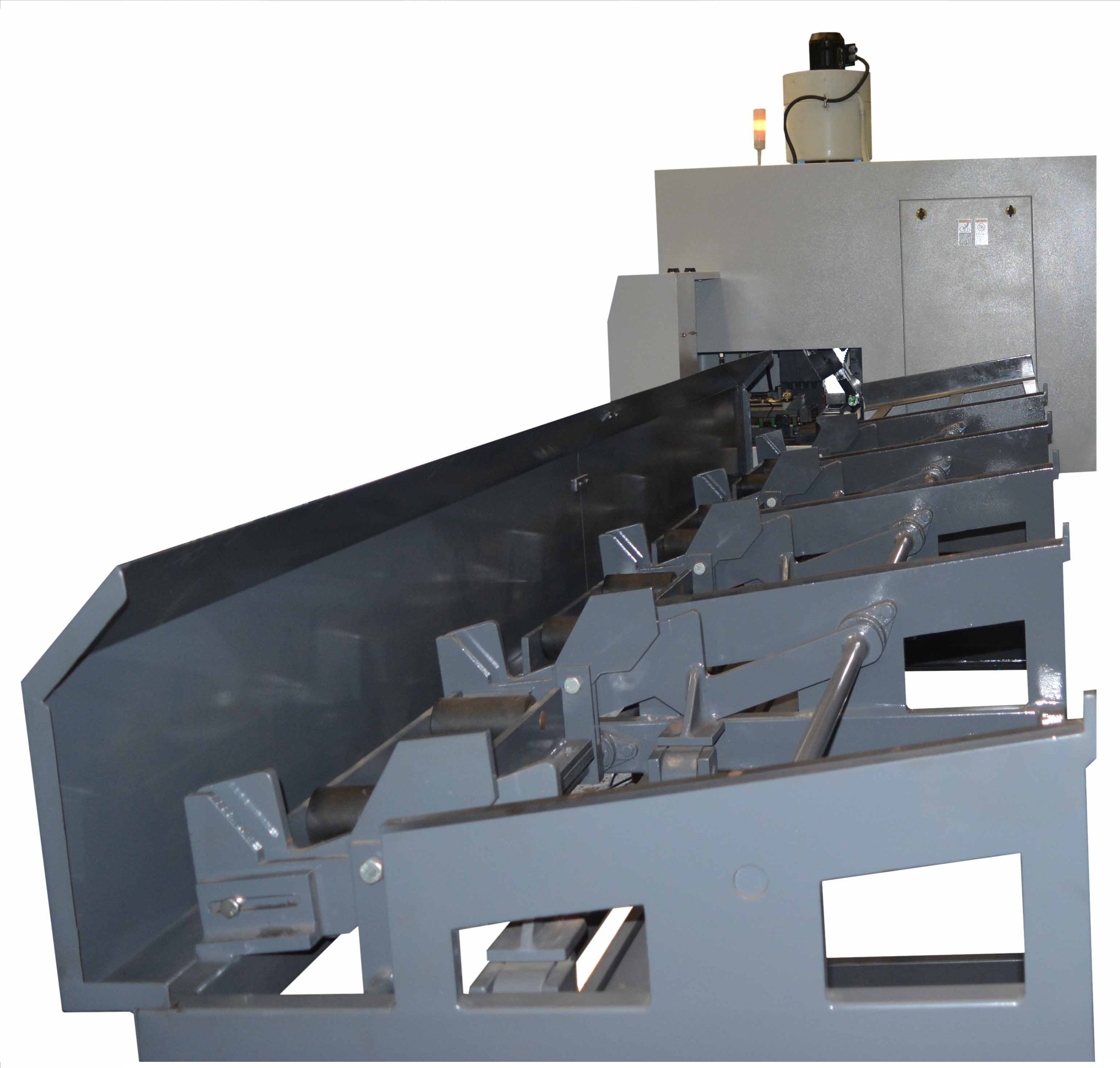

Types: Fully-Automatic / Semi-Automatic. 1) Fully Automatic BandSaw Machine: SILENT FEATURES *The machine is designed with robust, precision-engineered features to ensure high-performance cutting capabilities in demanding industrial environments. Key specifications include: *Main Saw Frame: Mounted on vertically hardened ground with hard chrome-plated columns for enhanced stability and durability. *Cutting Feed: Infinitely variable, providing controlled cutting feed adjustments for optimal performance. *Cutting Arm Movement: Rapid up-down motion powered by hydraulic cylinders for quick and precise operation. *Automatic Work Height Control: Equipped with a fast-approach bar sensor for precise and automated height adjustments. *Blade Guidance: Cutting tool (blade) is guided by two wheels made of graded cast iron for superior accuracy and smooth operation. *Hydraulic Vise System: Dual-vise, shuttle-type automatic feed with full-stroke clamping for secure and efficient workpiece handling. *Control System: NC controlled *Floating shuttle vise system for enhanced flexibility and versatility during operation. *Blade Support: Roller bearing system with carbide blade guides ensures stability and reduces wear on the blade. *Hydraulic Blade Tension: Equipped with a hydraulic blade tension arrangement to maintain optimal cutting conditions. *Job Clamping: Hydraulic-operated main vice for reliable job clamping during cutting. *Gearbox: Heavy-duty reduction gearbox for delivering high cutting torque necessary for heavy-duty applications. *Coolant System: Inbuilt coolant tank with a three-way cooling arrangement to ensure effective blade cooling and prolong blade life. *Chip Removal: Power-driven wire brush mechanism for automatic blade cleaning by removing chips. *Hydraulic Power Pack: Includes all necessary control valves, gauges, and oil level indicators for easy maintenance and efficient operation. *Chip Conveyor: Automatic chip conveyor for continuous chip removal, enhancing safety and cleanliness. *Electrical Control Panel: PLC-controlled electrical panel with high-quality switchgear for reliability and ease of control. *Cut Counter: Preset cut counter with automatic shutdown feature once the preset cut count is reached. *Safety Features: Machine automatically shuts off when the door is open for enhanced safety. *Idler wheel motion detector with automatic blade stalling and breakage shutdown to prevent damage and ensure safe operation. *Pulley System: Step pulley with 'V' belt for variable band speeds to accommodate various cutting applications. *Bi-Metal Saw Blade: One-piece bi-metal saw blade for increased cutting efficiency and durability. *Roller Stock Table: 1.5-meter-long roller stock table for easy material handling and support during operation. Standard Models: H320HA: Ø 320 (400W X 320H)mm 4HP Saw motor 2HP hydraulic motor Cutting Speed: 20-90 mtr/min Working Height: 670mm H400HA: Ø 400 (400W X 400H)mm 5HP Saw motor 2HP hydraulic motor Cutting Speed: 20-90 mtr/min Working Height: 670mm H500HA: Ø 500 (500W X 500H)mm 7.5HP Saw motor 2HP hydraulic motor Cutting Speed: 20-90 mtr/min Working Height: 790mm 2) Semi Automatic Horizontal Band Saw Machine: SILENT FEATURES: • Torsion free construction of Heavy-duty Fabricated Structure of Machine. • Main Saw frame guided on Vertical Hardened Ground and Hard chrome plated columns. • Infinitely variable controlled cutting feed. • Rapid Up - Down movement of Cutting Arm by Hydraulic cylinders. • Auto height stop arrangement of cutting Arm after completion of cut. • Cutting Tool (Blade) guided on the two wheel of graded cast Iron. • Tungsten Carbide faces Blade Guides. • Hydraulic Blade Tension Arrangement. • Hydraulic Operated job Clamping Main Vice. • Heavy duty reduction Gearbox for heavy cutting torque. • Inbuilt coolant tank with three-way cooling arrangement. • Chips removing wire brush arrangement for cleaning of blade. • Separate Hydraulic Power pack with all control valves, gauges & Oil level Indicator for easy check & maintenance. • Electrical Control Panel with RLC and high-quality switch gears • VFD speed control. • One piece of bi-metal saw blade. • Models H-280, H-350, H-400, H-40/60, H-40/70

Send Message